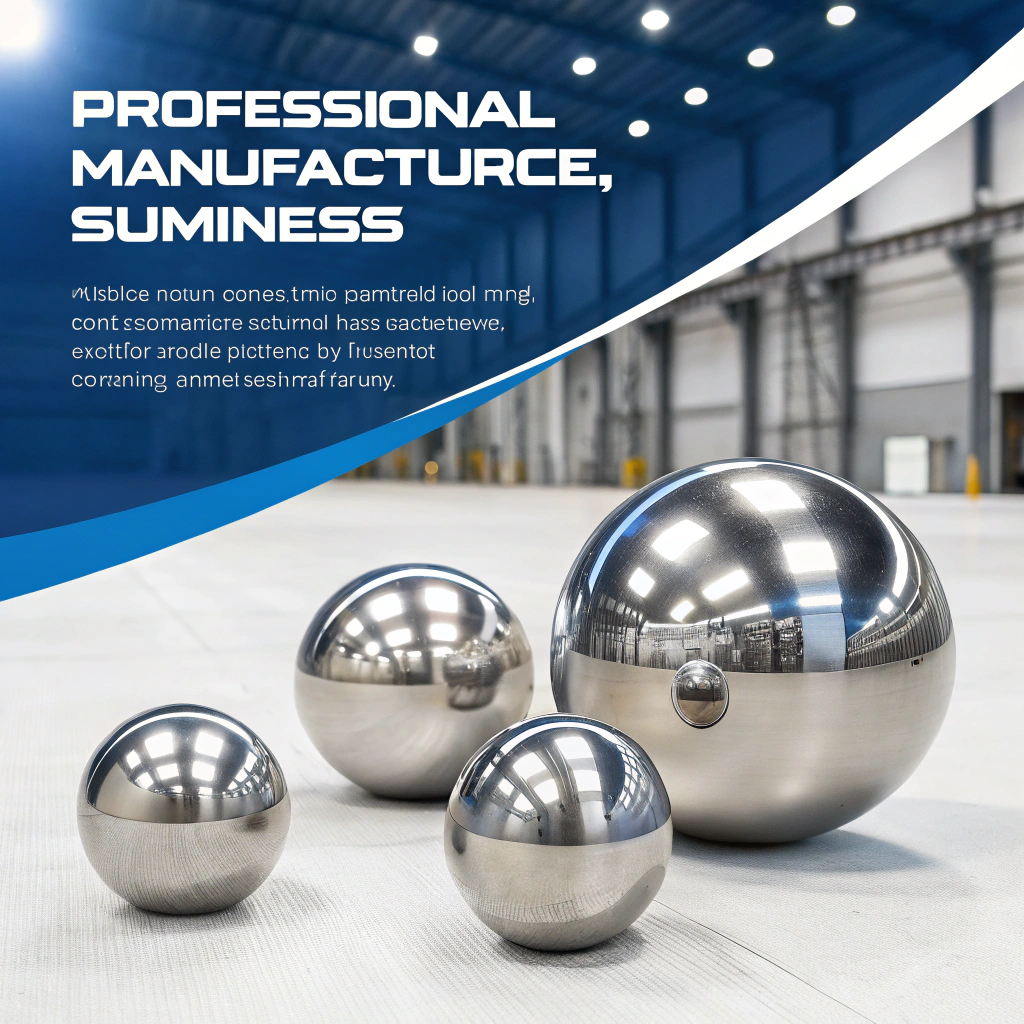

Product Overview

Our SUS304 stainless steel balls are precision-machined from premium grade 304 stainless steel material, featuring outstanding corrosion resistance and mechanical strength. With a diameter of 6.35mm and G10 precision grade, these balls have a mirror-like surface finish and are widely used in bearings, valves, measuring equipment, and other precision applications.

Product Features

• Premium SUS304 stainless steel material with excellent corrosion resistance

• G10 high precision grade ensuring dimensional stability

• High surface finish with low friction coefficient

• Food-grade safe for food contact applications

• Consistent quality through mass production

Technical Specifications

| Parameter | Value | Parameter | Value |

|———–|——-|———–|——-|

| Diameter | 6.35mm | Material Grade | SUS304 |

| Precision Grade | G10 | Surface Hardness | HRC25 |

| Sphericity Error | ≤0.5μm | Surface Roughness | Ra≤0.05μm |

| Weight | 1.04g | Density | 7.9g/cm³ |

| Working Temperature | -40~200℃ | Magnetism | Non-magnetic/Weak |

| Diameter Tolerance | ±0.005mm | Packaging | 1000 pcs/pack |

Material Properties

• Premium SUS304 stainless steel** meeting international standards

•Excellent corrosion resistance** for various environments

• Good mechanical strength and toughness**

• Non-magnetic or weakly magnetic** for precision applications

• Food-grade safety** suitable for food contact applications

Manufacturing Features

• Precision cold heading process** ensuring dimensional accuracy

• Multiple grinding and polishing** for mirror-like surface finish

• Strict quality control** with stable batch quality

• Advanced heat treatment process** for optimized performance

• Automated production line** ensuring consistency

Applications

• Precision bearing manufacturing – Excellent rotational performance

• Valve sealing systems** – Reliable sealing effectiveness

• Measuring and testing equipment – Guaranteed measurement accuracy

• Chemical equipment components- Outstanding corrosion resistance

• Food processing equipment – Meets food safety standards

• Medical device components- Good biocompatibility

Quality Assurance

We maintain a comprehensive quality control system with rigorous testing for each batch to ensure products meet international standards. ISO9001 certified quality management system provides reliable quality assurance for our customers.